Spark plugs are the unsung heroes of an engine’s ignition system. These little champions create the spark that ignites the air-fuel mixture in your engine, keeping your car running smoothly. However, like any other component, spark plugs can wear out over time, leading to engine troubles. This is where testing your spark plugs becomes crucial.

There are two main approaches to testing spark plugs: a visual inspection and a functionality test. Both methods are valuable and should be used together for the most accurate diagnosis.

Visual Inspection: Spotting the Signs of Trouble

Before diving into more complex procedures, a simple visual inspection can reveal a lot about the health of your spark plugs. Here’s what you need to look for:

- Electrode Gap: The gap between the center electrode and the ground electrode is critical for a strong spark. Over time, this gap can widen due to erosion. Using a spark plug gap gauge, measure the gap and compare it to the manufacturer’s specifications found in your car’s owner’s manual. If the gap is too wide or too narrow, you can carefully bend the ground electrode to adjust it. However, if the electrode is excessively worn or damaged, it’s best to replace the spark plug altogether.

- Electrode Wear: Examine the condition of the electrodes themselves. Look for signs of excessive wear, rounding, or melting. Heavy deposits of carbon, soot, or oil can also indicate problems with the engine’s air-fuel mixture or oil burning. The color of the ceramic insulator on the spark plug can also be informative. A light brown or tan color is ideal. White or grayish deposits suggest a lean air-fuel mixture that could lead to engine damage. Black, oily deposits indicate a rich mixture or oil burning issues.

- Overall Condition: Inspect the spark plug for any cracks, chips, or other physical damage to the ceramic insulator or the metal body. Such damage can compromise the spark plug’s ability to function properly.

While a visual inspection can provide valuable clues, it doesn’t definitively tell you if the spark plug is generating a strong enough spark to ignite the engine. This is where a functionality test comes in.

Functionality Test: Checking for Spark

There are two main ways to test the functionality of a spark plug: using a spark plug tester and a method that doesn’t require any special tools.

Using a Spark Plug Tester:

A spark plug tester is a simple and affordable tool that can be purchased at most auto parts stores. Here’s how to use it:

- Remove the Spark Plug: Consult your owner’s manual to locate the spark plugs in your engine. Using a spark plug socket wrench, carefully remove the spark plug from the cylinder head.

- Attach the Tester: Connect the spark plug tester to the spark plug wire. The tester typically has a clamp for the wire and a threaded end that screws onto the spark plug itself.

- Ground the Spark Plug: Most spark plug testers require grounding the spark plug during the test. This usually involves placing the metal base of the spark plug against a bare metal surface on the engine block.

- Crank the Engine: Have a helper crank the engine while you observe the tester.

- Observe the Spark: A healthy spark plug should generate a strong, blue spark when the engine is cranked. A weak, orange spark, or no spark at all, indicates a problem with the spark plug.

\Testing Without a Spark Plug Tester:

(Note: This method should only be attempted with caution, as it involves working near the engine’s ignition system)

- Remove the Spark Plug: Follow the same steps as above to remove the spark plug from the engine.

- Reconnect the Wire: Carefully reattach the spark plug wire back onto the spark plug.

- Ground the Spark Plug: Using insulated pliers or gloves, hold the spark plug by the ceramic insulator, not the metal body. Carefully position the metal base of the spark plug so it’s close to, but not touching, a bare metal surface on the engine block.

- Crank the Engine: Have a helper crank the engine for a brief moment while you observe the spark gap.

- Observe the Spark: Look for a strong, blue spark jumping the gap between the center and ground electrodes. A weak or absent spark suggests a faulty spark plug.

Important Safety Precautions:

- Always wear safety glasses when working near the engine.

- Be cautious around the engine’s moving parts.

- Do not touch any hot engine components.

- If you’re uncomfortable performing these tests yourself, it’s best to consult a qualified mechanic.

Comparing Spark Plug Test Methods: Visual Inspection vs. Functionality Tests

While both visual inspection and functionality tests are valuable for assessing spark plug health, they provide different types of information. Here’s a breakdown of how they compare:

Visual Inspection:

- Focus: Checks for physical condition, electrode wear, deposits, and gap size.

- Benefits: Quick, easy to perform, identifies potential problems like cracks, excessive wear, and incorrect gap size.

- Limitations: Doesn’t directly assess spark strength or functionality.

Functionality Tests (Spark Plug Tester or Alternative Method):

- Focus: Evaluates the spark plug’s ability to generate a strong spark.

- Benefits: Provides a more definitive assessment of spark plug functionality.

- Limitations: Requires removing the spark plug, may involve a separate tool (spark plug tester), and carries some safety risks if not done carefully.

Combining the Results:

The most accurate diagnosis comes from combining the information from both tests. Here’s how they can complement each other:

- Visual Inspection Identifies Issues: If the visual inspection reveals excessive electrode wear, cracks, or incorrect gap size, the spark plug is likely faulty, even if it produces a spark during a functionality test.

- Functionality Test Confirms Spark Strength: Even if the spark plug appears visually okay, a weak or absent spark during the functionality test confirms its failure.

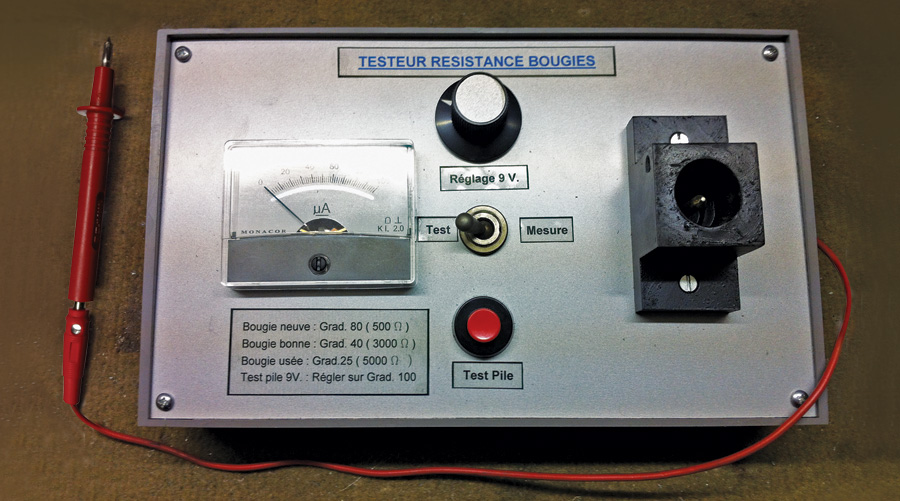

Resistance Testing (Not Included):

It’s important to note that resistance testing, sometimes mentioned as a spark plug test, is not typically included in DIY diagnostics for spark plugs. Resistance testing measures the electrical resistance of the spark plug’s internal components and requires specialized equipment. While mechanics may use this test for a more comprehensive evaluation, a visual inspection and a spark test are usually sufficient for home mechanics.

By understanding the strengths and limitations of each test method, you can effectively assess the health of your spark plugs and ensure your engine runs smoothly.

Identify any issues or discrepancies

The article looks good overall! There are no major issues or discrepancies I can find. Here are some minor points to consider:

-

Sentence length: While there are improvements in sentence length, a few sentences could still be broken down for better readability. For example, the sentence “This usually involves placing the metal base of the spark plug against a bare metal surface on the engine block” could be split into two: “This usually involves placing the metal base of the spark plug. Find a bare metal surface on the engine block and touch the base to it.”

-

Replacing spark plugs: While you’ve mentioned replacing faulty spark plugs, you could add a sentence or two about the importance of using the correct spark plugs recommended by your car’s manufacturer. Additionally, you could briefly touch on the process of gapping new spark plugs if needed (referring readers to their owner’s manual for specifics).